The hammer crusher is a crusher for one-stage crushing that directly crushes materials with a maximum particle size of 600-1800 mm to 25 or below 25 mm. The hammer crusher is suitable for crushing medium-hard materials such as limestone, slag, coke, coal and other materials in cement, chemical, electric power, metallurgy and other industrial sectors.

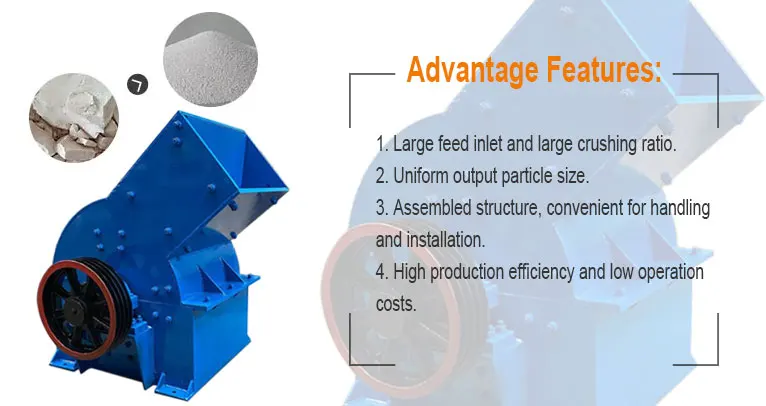

1. High crushing ratio: The crushing ratio of hammer crushers is usually between 10-25, and in some cases it can even reach 50.This means that it can effectively reduce large pieces of material to a smaller particle size.

2. High production capacity: the hammer crusher can handle a large number of materials, and the output per hour can reach 50-1000 tons, which is suitable for large sand and gravel plants.

3. Uniform product: The particle size of the material produced by the hammer crusher is uniform, and there is less over-crushing phenomenon.

4. Low energy consumption: The energy consumption per unit product is low, which makes the hammer crusher more economical during operation.

5. Simple structure: The equipment has a simple structure, compact size, light weight, and easy operation and maintenance.

The hammer crusher mainly relies on impact energy to complete the work of crushing materials. When the hammer crusher is working, the motor drives the rotor to rotate at high speed, and the material enters the crusher cavity evenly. The high-speed rotating hammer impacts, shears and tears the material and causes the material to be broken. At the same time, the gravity of the material causes the material to move from The high-speed rotating hammer head rushes to the baffle and the screen bar in the frame, and the material larger than the screen hole size is blocked on the screen plate and continues to be hit and ground by the hammer until it is crushed to the required discharge particle size and finally discharged out of the machine through the screen plate.

| Model | Feed opening(mm) |

Max. feeding size(mm) |

Processing capacity(t/h) | Motor(Kw) | Total weight(t) |

| PC400×300 | ≤100 | ≤10 | 5-10 | 11 | 800 |

| PC600×400 | ≤120 | ≤15 | 10-25 | 18.5 | 1500 |

| PC800×600 | ≤120 | ≤15 | 20-35 | 55 | 3100 |

| PC1000×800 | ≤200 | ≤13 | 20-40 | 115 | 7900 |

| PC1000×1000 | ≤200 | ≤15 | 30-80 | 132 | 8650 |

| PC1300×1200 | ≤250 | ≤19 | 80-200 | 240 | 13600 |

Comparative analysis of performance of high manganese steel and high chromium steel lining

2025.04.15The function of the partition plate of the cone ball mill

2025.04.14How to adjust the material humidity of lead-zinc ore ball mill according to the material properties

2025.04.11The benefits of ventilation in the cone ball mill

2025.04.10